- Reaction score

- 18,368

- Points

- 1,010

They aren’t even used! Some of them are being delivered straight from the builder to the Reserve Fleet!Alex, I'll take "Why don't we buy used junk from other Navies anymore" for $1000?

They aren’t even used! Some of them are being delivered straight from the builder to the Reserve Fleet!Alex, I'll take "Why don't we buy used junk from other Navies anymore" for $1000?

Let's let them soak for a decade, then pick them up at a huge mark-up.They aren’t even used! Some of them are being delivered straight from the builder to the Reserve Fleet!

there is good reason why the yanks do not want floating lemons, starting with mechanical issuesFreedom class LCS it is, excellent choice.

there is good reason why the yanks do not want floating lemons, starting with mechanical issues

I got that.there is good reason why the yanks do not want floating lemons, starting with mechanical issues

Nope. Less CPFs beats all the CPFs, and ITAR is a nightmare.I got that.

Still, we might be soon reaching a point where a (theoretically) mechanically unreliable warship beats a CPF…

BC Ferries has some lightly used options...Alex, I'll take "Why don't we buy used junk from other Navies anymore" for $1000?

Actually I bet they are better built than the LCS'sBC Ferries has some lightly used options...

WTF? wow or is someone exaggerating?We're not the only one with delays. Apparently the USN sub program is a solid 400 months behind schedule (aka 33+ years).

The AOR replacement project has been ongoing since the 80s I think, depending on what they are using to get that number. There were two restarts and an unsuccessful RFP (because the big honking ship was impossible to build below the dollar value requirement). If you include the pre NSS efforts of JSS we're probably at over 40 years now.We're not the only one with delays. Apparently the USN sub program is a solid 400 months behind schedule (aka 33+ years).

The AOR replacement project has been ongoing since the 80s I think, depending on what they are using to get that number. There were two restarts and an unsuccessful RFP (because the big honking ship was impossible to build below the dollar value requirement). If you include the pre NSS efforts of JSS we're probably at over 40 years now.

The AOR replacement project has been ongoing since the 80s I think, depending on what they are using to get that number. There were two restarts and an unsuccessful RFP (because the big honking ship was impossible to build below the dollar value requirement). If you include the pre NSS efforts of JSS we're probably at over 40 years now.

The way the RFP was structured was fundamentally flawed; the requirements would have been okay if there wasn't a hard max bid value. There was no ability to cut capabilities in normal trade offs so it made no sense. Ask for the world if you want, but don't have a dollar value limit.This one kind of bothers me.

Come the day, when we want to get kit from Canada to Riga or Tokyo, what type of hull are we going to charter to get there? I would suggest "any available" and it will likely be built to civvy standards.

Will it require an escort? Probably. But there again so would a MilSpec ship loaded with an army's worth of kit.

So do we really have to pay the price for the MilSpec transport capability?

Or could we just go the Point Class RoRo route - chartered by MOD but also used on the civvy market.

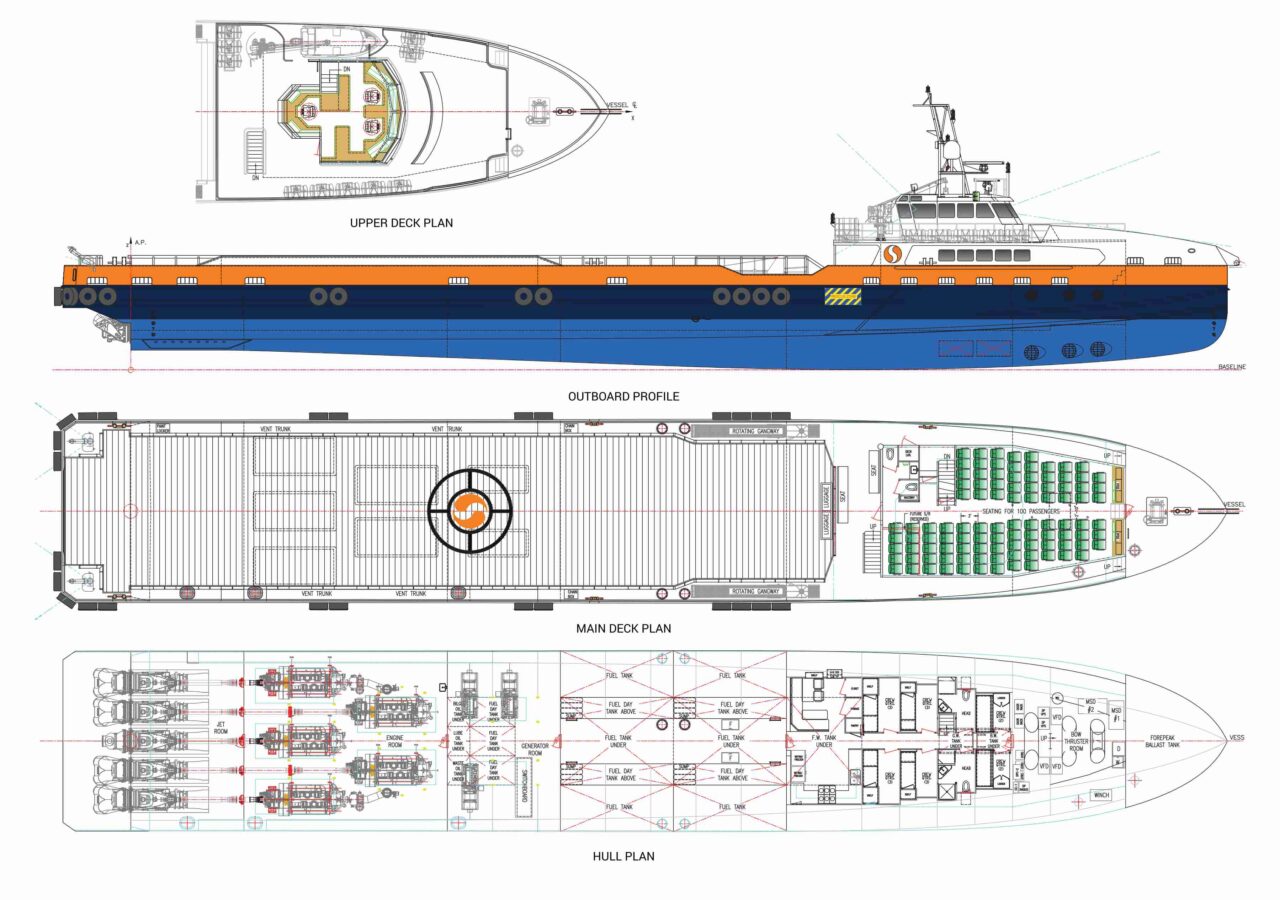

View attachment 82572

Point-class sealift ship - Wikipedia

en.wikipedia.org

We planned on expanding the USN SSN fleet without fully engaging with industry and don’t understand the effects that COVID had on industry. As well Industry BD folks tend to over promise.WTF? wow or is someone exaggerating?

The way the RFP was structured was fundamentally flawed; the requirements would have been okay if there wasn't a hard max bid value. There was no ability to cut capabilities in normal trade offs so it made no sense. Ask for the world if you want, but don't have a dollar value limit.

From talking to someone that retired after spending their entire career on the 3, the first project never got to the approval point of getting funded by TBS, so was more a Canada defence funding thing, as I guess they figured the status quo was enough.

Even then, government procurement adds a lot of process, risks and costs which the GoC pretends don't exist. There isn't a good way to say 'propose something you can deliver for $X' unless it's simple and quick delivery, plus would be impossible to compare bids for scoring. Our entire RFP process is designed against setting a standard, then people bid against that standard, with extra points for various add ons.Or, if you have a dollar value limit be prepared to buy what you can afford and live with those limits.

Even then, government procurement adds a lot of process, risks and costs which the GoC pretends don't exist. There isn't a good way to say 'propose something you can deliver for $X' unless it's simple and quick delivery, plus would be impossible to compare bids for scoring. Our entire RFP process is designed against setting a standard, then people bid against that standard, with extra points for various add ons.

NSS kind of did that, except we selected a partner shipyard for the build so gives us more freedom to change the actual ship requirements (which can be good and bad).

I work in tech and though I'm not invovled directly with any aquisition, I've seen us move from having litterally several dozen products and vendors all manually tied into each other to just a handful of vendors (mostly Microsoft). The 99% perfectness of a bespoke solution just became too expensive and required too much institutional knowledge to be worth it over a 90% solution that does everything we need and is only missing some quality of life features.My inclination is always to the second case because my experience working for suppliers tells me that even if I buy everything separately with the deepest discounts on the market the suppliers (plural) are still making money and the customer is on the hook for the integration and takes responsibility for the errors. By the end of the commissioning stage any deep discount savings are long gone and the plant is well behind schedule.

The alternative, trusting a single vendor, gets me a faulty solution, but one that is probably less faulty than the deep discount solution and easier to bring up to the desired operating standard.